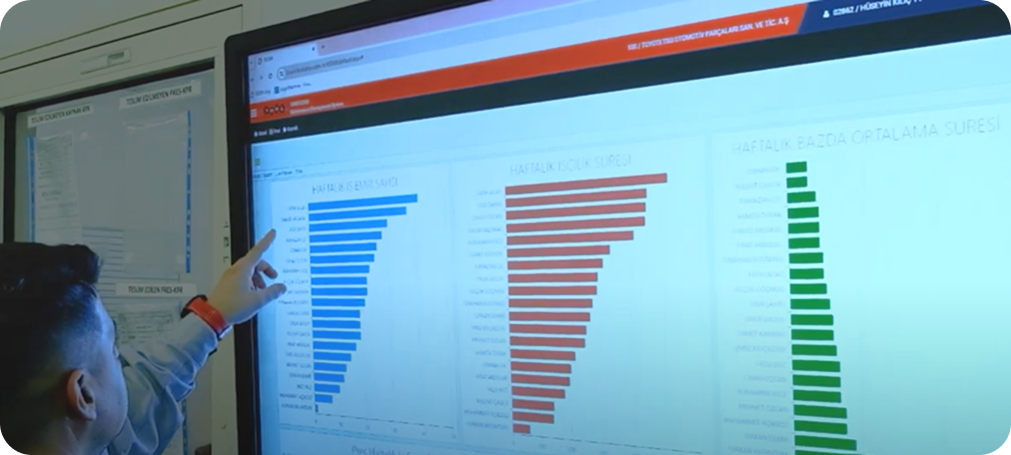

For 2024, we are successfully progressing towards our goal of achieving a minimum 10% reduction in downtime by starting to use the Dashboard application effectively.

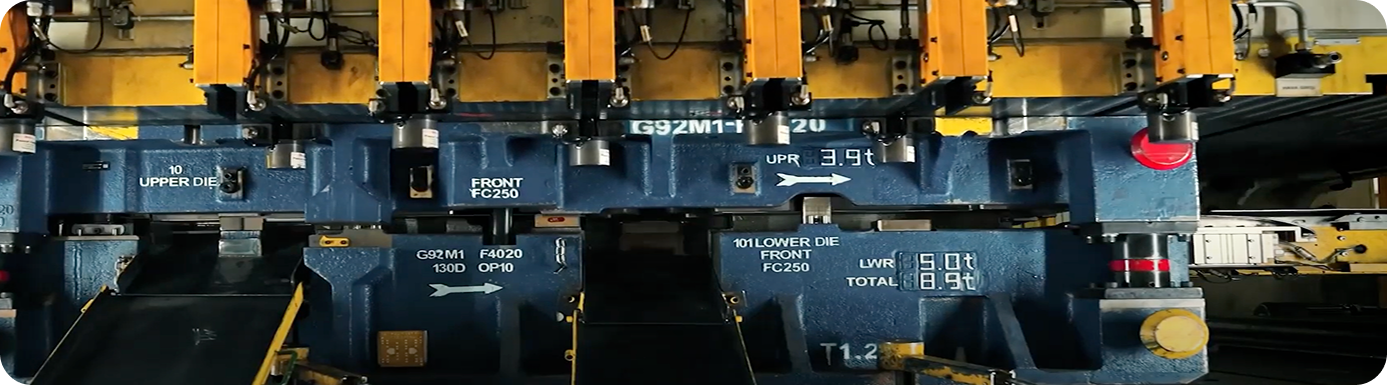

Toyotetsu Turkey was established in Gebze TOSB in 2001 and started production in 2002. With a 62.700 square meter closed area, the company has 2 factories, 1 R&D Center, 1 mold factory, 180 robots, 7 transfer, 3 blanking, 3 hot pressing, 3 laser cutting and 4 tandem press lines. The company has a total of 1270 employees. Toyotetsu Turkey serves as the only production and R&D Center in the European continent among the group companies producing high-strength cold and hot formed automotive body and chassis parts.

Before using bEAM, Toyotetsu managed assets on paper and Excel spreadsheets. These analog methods made it difficult to track the addition, movement and removal of assets. Keeping records of maintenance and breakdowns was cumbersome, reporting and tracking historical records was time-consuming, which reduced the efficiency of business processes and increased the error rate. As the needs of the organization grew, these legacy solutions proved inadequate, making it important to look for a more effective solution. bEAM provided a more effective solution that responded to growing organizational needs.

bEAM Enterprise Asset Management solution covers all asset-related processes, from adding assets to inventory to scrapping them. The solution also identifies the causes of asset failures, compares the purchase price of your assets in foreign currency with the cost of materials and labor spent on the asset, and provides your management with information to support their decisions on the economic life of your assets.

Toyotetsu chose bEAM to ensure effective asset and maintenance management. The main objectives and KPIs of the project were:

Toyotetsu has digitized asset and maintenance management with bEAM, enabling rapid detection of faults and automated maintenance processes where analog methods are insufficient.

Robotic Automation and Vocational Training Specialist

The benefits and results of the project have been quite significant:

Saved per year for maintenance managers

Reduction in parts inventory costs

Reduction in unplanned downtime

Companies reported reduced safety risk

Equipment availability improved by 25% with digital EAM.

Preventive maintenance time reduced by 35%.

Operational safety enhanced by 28%.

22% boost in meeting sustainability goals.

Of companies that digitized asset management reduced maintenance costs

Drop in unplanned downtime

Decrease in asset lifecycle costs

Predictive maintenance + IoT reduced ownership costs by 20%

Faster decision-making

Lower carbon footprint

We are thrilled to share that we participated in the Acumatica

Our Global PMO Product Manager, Ege Berkay Bozkurt, proudly represented bEAM

bEAM Cloud proudly participated in the SAP Sapphire & ASUG Annual